Design and Development

Total 360 degree Engineering Solutions

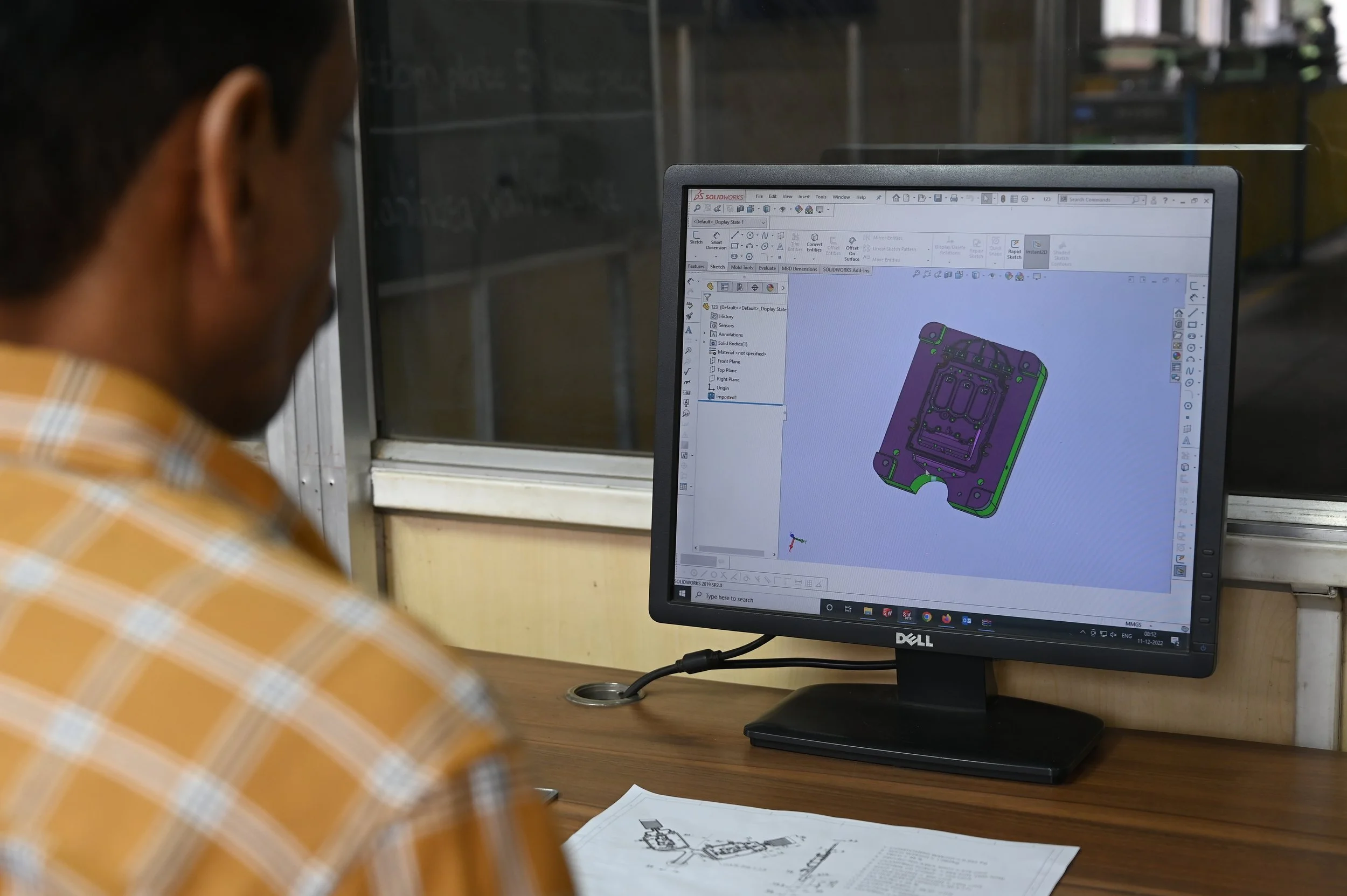

Our Inhouse Development facility undertakes 3D die design using Unigraphix NX and die manufacturing using UG Cam & Master Cam for tool development. All our designs are reviewed for Design For Manufacturability ( DFM ) & Design for excellence ( DFX ) and engineering changes are executed as needed. Mold flow analysis is used for die design validation.

Computerized Designing

Precision Tooling & Die making are the very heart of the Die Casting & Machining processes & are critical to the quality of the final products. Our in-house temperature controlled Tooling & Mold Making Department uses the most advanced equipment available today. We deploy a number of Dedicated Die mold VMCs, EDM, & wire cutting setups. Our Die shop is fully computerized with professional die makers cross trained in all methods of machining. This combination of equipment, software, talent and creativity, results in top level quality & precision as well as dramatic savings of time and overall cost. Our Tooling & Die Making departments combine flexibility & productivity with the highest technological features & are capable of manufacturing complex workpieces, thereby meeting the high demands of a wide variety of advanced manufacturing.

Precision Tooling & Die Making

The broad-based and rich technical expertise & sound manufacturing experience at Menon Alkop enables us to provide total engineering solutions to our customers. From concept, design, testing & validation to final production. Our team of design engineers interact closely with our OEM customers in arriving at a proper solutions through a collaborative effort. Highly qualified & trained engineers with exposure to international trends in technology, product designing, different work situations, are capable of structured problem solving & developing robust solutions for continuous process re-engineering. Many OEMS have used the services of our design engineers to generate new ideas & solutions for existing & new products. We have supported engineering programs of various OEMS worldwide. Our fully integrated systematic approach has won many awards for quality and manufacturing excellence.